In metal shielding gas (MIG) welding, two metal parts are connected to each other when consumable wires introduced into a welding gun are connected with an electrode and current. Almost every project is undergone by the welding team at some point in the production process. Although each method has its own strengths and situational roles, understanding the different welding methods available to welders and their respective teams can provide greater insight and clarity into the manufacturing processes. Welding is one of the most important aspects of any welding project, not only in manufacturing but also in construction.

A shielding gas protects the electrodes from contamination when the wires pass through the gun, and the electrode is also protected from contamination by the shielding gases.

Unlike MIG welding, no additional metals may be used as welding material in TIG welding, and in contrast to Mig welding robots, a Tig welding machine is programmed for welding. To ensure better consistency, the robot can also be programmed to perform the welding work without a human welder to monitor it.

Finding an experienced Local MIG Welder

In the welding a metal fabrication game, it is very likely that the custom welding services that serve your area are able to handle all welding types including MIG, TIG, Arc and oxy-acetylene. In all likelihood, they can also handle the other modifications needed for your custom metalwork project.

If you are not looking to hire a metal fabricator to do the work and consider yourself pretty ‘handy’, you may want to look at purchasing a machine and attempting to do the work yourself. Multi-process inverter welding machine are readily available these days at very reasonable prices.

When using an automated welding machine, whether MIG or TIG, it is important to make the right welding settings and controls, otherwise you risk repeating the same mistakes over and over again.

How does MIG welding Work?

As already mentioned, I preferred TIG to MIG because it has to be welded with different metals. However, it can work wonders to connect small pieces of metal like wire with a bespoke wire basket. As a filler material, it can also be used to join large, thick pieces of metal, but it is much more difficult to use than joining a small, thin piece or even a single piece.

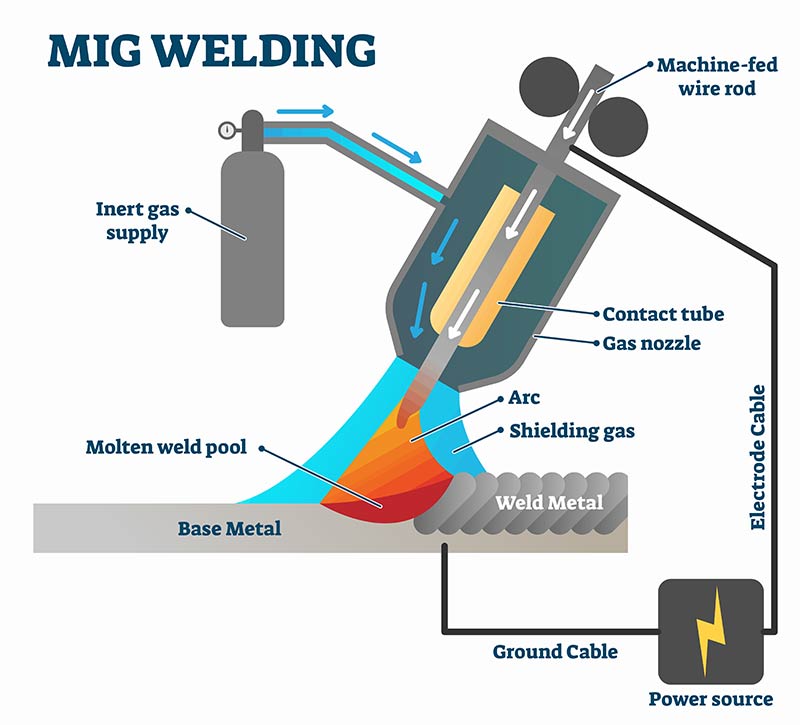

This diagram shows how the MIG welder works:

If you want to weld stainless steel or aluminum alloys, then TIG is your choice, but for heavy manufacturing arc welding is great. Tig won every time I did my motorcycle project and I chose him because the welding control is much better, although I have welded with stainless steel and aluminum alloy. However, if you are welding with arc welding, you should choose Tigs because of the welding control.

TIG welding costs more than MIG, because TIG is a much more laborious process and because the material actually used for TIG welding is much cheaper than other welding processes such as arc welding, there is also a difference in the length of welding time according to the Tigs process, which makes the welding process more expensive.

If you can answer a few questions, it is usually easy to determine which welding method is best suited for a particular task.

When it seems obvious, G.E. Mathis & Company provides precision welding services to meet the customer’s exact specifications. Marlins engineering team uses virtual physics simulation software to check if the weld is working as expected.

Our precision arc welding services are available for a variety of metals, including steel, aluminum, copper, nickel, stainless steel and other metals. We weld TIG welds in our small machine shop, but we also provide a variety of other welding and metal manufacturing services for industrial and commercial applications. Our precision welders in the U.S. and Canada and overseas provide services to industries such as agriculture, mining, aerospace, construction and military, among many others.

It’s difficult to do all this in addition to your full-time job because it really locks you in at nights and weekends. Every day when you come home you have something new and crazy to work on, but it’s always a challenge.

MIG welds are usually not as clean as TIG welds when performing well, but higher efficiency can be an advantage. Adjustments to the welding gun do not have to be made as often, so that welders can concentrate on individual welding for a longer period of time.

In addition, MIG welding is easy to learn for both newly trained professional and amateur welders. This process tends to be a little more lenient than TIG welds and is often recommended, but it is still not as simple as Tig welding.

TIG welding, on the other hand, requires the use of timing, pressure and electric current for welding, but can be carried out with an automated, computer-controlled (CNC) welding machine. This machine can perform identical welds in less time than a manual welder could with manual welders, and can perform a control weld with only a small amount of time and a very low number of electric currents.

If you want to weld a heavy steel plate quickly, you can switch to the arc function, and if you have a TIG welding machine, think it will give you a high degree of flexibility to customize your motorcycle. You can weld thin steel or aluminium alloys with Tig functions or build a workbench with a toolbox.

Welding technology has developed to the point where there are high-quality welding machines today. You should buy a welding machine as an investment that should last you a lifetime and not just a few years.